Share

Welding aluminum is no small feat, especially when crafting frames for high-performance racing simulators. At Novus Sim Racing, the team leverages decades of experience to overcome the material’s unique challenges, ensuring every frame is straight, strong, and built to last.

Aluminum’s appeal lies in its lightweight strength, making it perfect for simulator frames. Yet, its high thermal conductivity poses a problem: it transfers heat rapidly during welding, increasing the risk of warping. For a simulator, where precise alignment is non-negotiable, even slight distortions can undermine performance.

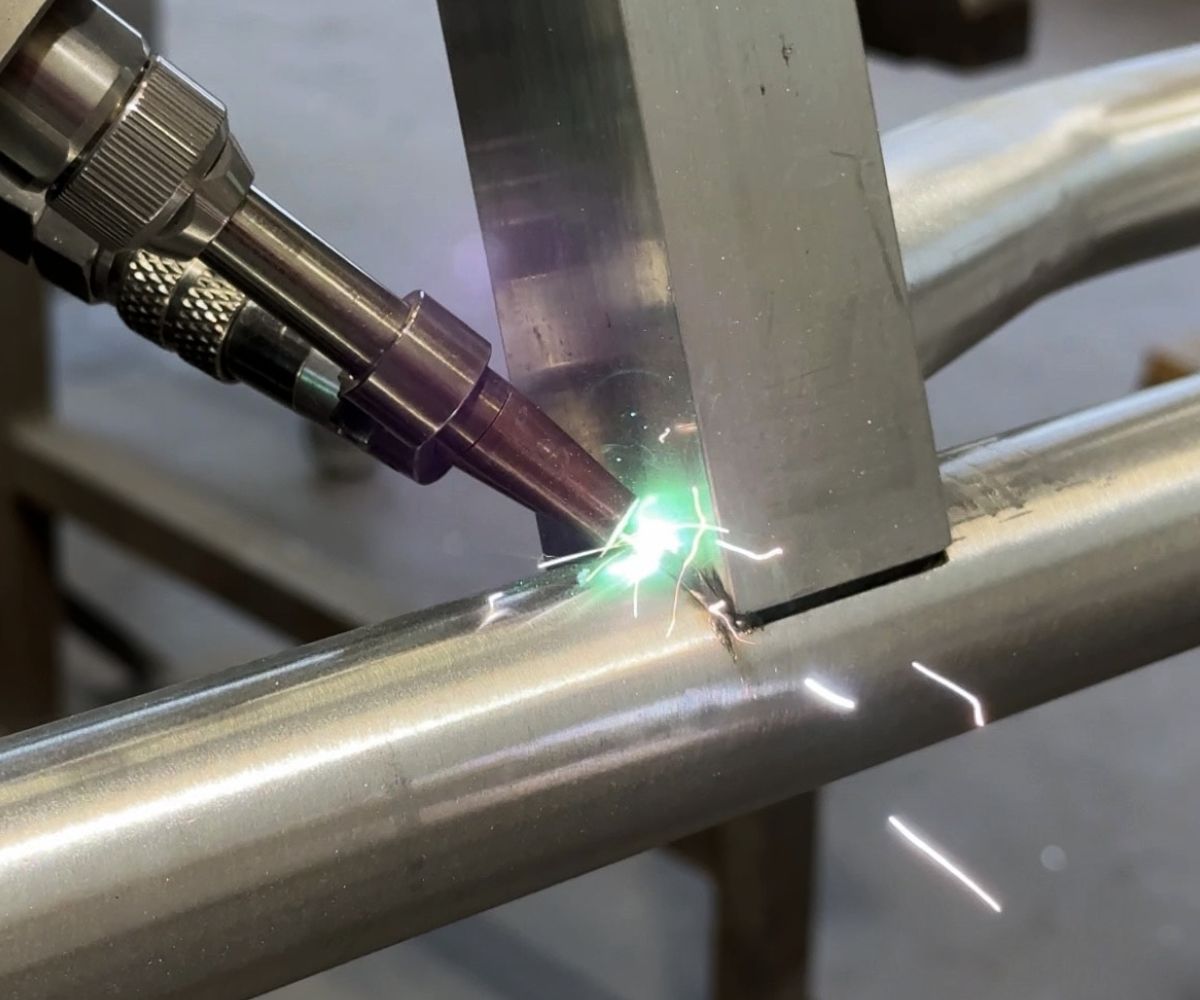

To address this, Novus uses precision jigs. These tools hold prepared aluminum tubes in exact positions, preventing movement during welding and ensuring the frame’s shape remains true. However, traditional welding methods still introduced excessive heat, leading to compromises—until the team adopted laser welding technology.

Laser welding delivers a concentrated, high-energy beam, minimizing the heat-affected zone. This precision reduces warping, producing clean, strong welds that enhance both durability and aesthetics. The result? Frames that meet the exacting standards of serious racers.

CEO Grega Zust showcases this process in a recent Instagram reel, walking through the fabrication steps. With over 30 years of welding expertise, Novus continues to push the boundaries of simulator design.

Ready to experience this precision firsthand? Explore our simulators.